As suspected, a few minor goof-ups already spotted on the Next mini one, and the C64 one too. The Amiga one’s looking ok so far….

Still a few weeks of testing needed though before a production run can happen!

As suspected, a few minor goof-ups already spotted on the Next mini one, and the C64 one too. The Amiga one’s looking ok so far….

Still a few weeks of testing needed though before a production run can happen!

Woooo!

Should be here next week, not long till I find out how badly I’ve cocked them all up and how much work needed for a re-spin for production!

I purchased 2000 switches so can re-spin and re-test one, possibly two depending on which one (the Amiga needs 500 switches for 5 keyboards, spectrum needs far fewer!!)

Exciting times, now gotta get off my bum and fire the resin printers up.

Yep, these are WORKING keyboards for the

The A500 Mini Amiga

The C64 Mini Commodore 64

And

The Spectrum Next Mini (an Xberry Pi case) which is a 50% X &Y (100% Z) scale next mini styled case.

Tad hungover on new years day, plenty of time to ruminate, so…decided to work on the last (which is the first!) of the keyboards…had a solid 4 or 5 hours to myself today so made a lot of progress!

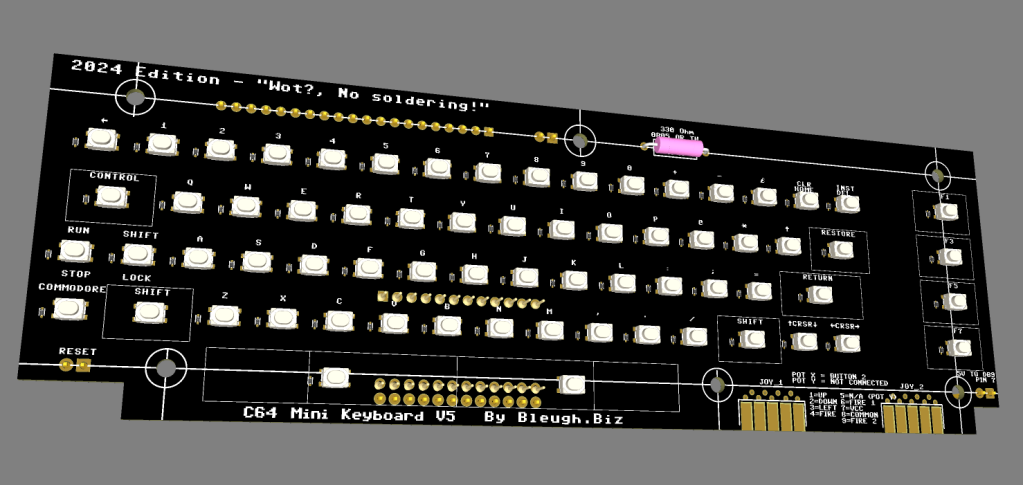

Have finally made the C64Mini one in surface mount – Now i’ve sourced a supplier of suitable, well priced keyswitches, I’ve felt it worthwhile to re-visit this project…

What SMT means – Very little soldering needed for this prodcut. Just the Arduino pro-micro at this time.

I’m hoping this makes the kit much more accessible, many will put their hands up and state that the 600+ solder joins needed on the old one was ‘painful’….

Some pics!

Top of the board – based on the modified 4.1

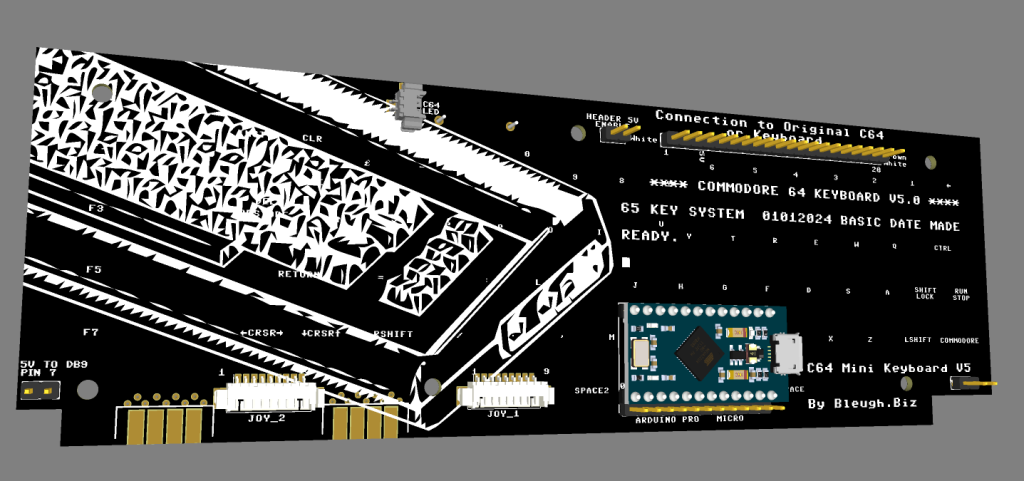

Bottom of the board..

Next step is changing the schematic over to use the much more readily available Raspberry Pi Pico or even creating a dual footprint board so you select which microprocessor to use, either the 32u4/Arduino Pro Micro or the Raspberry Pi Pico.

Unsure how i’ll offer the kits, I may well just pre-solder the microprocessor on so it’s a truly plug and play kit!

Still have to route the board, which will take a couple of days.

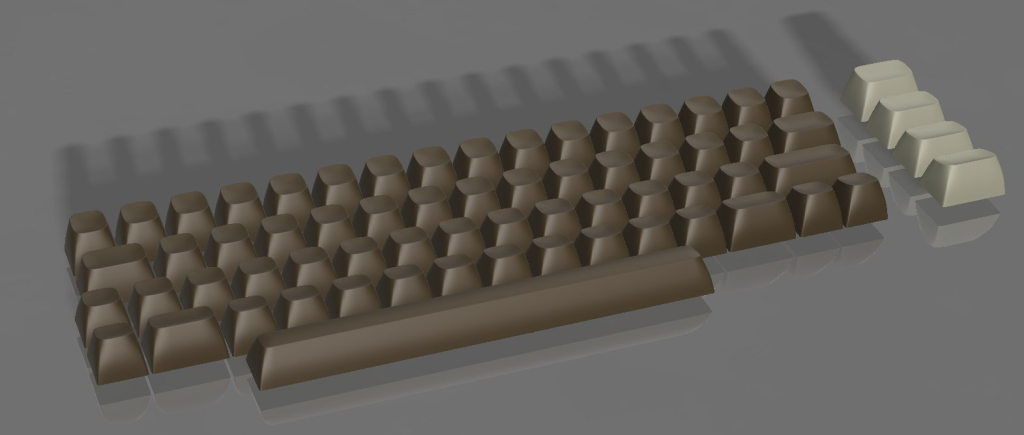

Also have started re-designing the keycaps from scratch – the old CAD is nigh on impossible to manipulate due to being so complex (was my first complex CAD project after all), so it’s easier to start over – and…I’ve gotten this far after just a week or so of playing

Keycaps re-done – Just needs the lettering and symbols!

I’m hoping to get this finished in time to add to my batch order of Next Mini and Amiga mini prototypes

I had somewhat of a PETSCII induced fever over the past few weeks, one that needed Sating before I could practically start anything anew, or even continue anything existing……..

So, when I (eventually) re-make the C64Mini keyboard kit to be less soldery, more easierer and betterer, It may well have PETSCII on those keycaps, for all your milliputty smudgery into-ey goodness!

A500 Mini Prototype 2 is in the post, Every C64Mini keyboard kit and parts have been posted – I’m finally fully up to date!

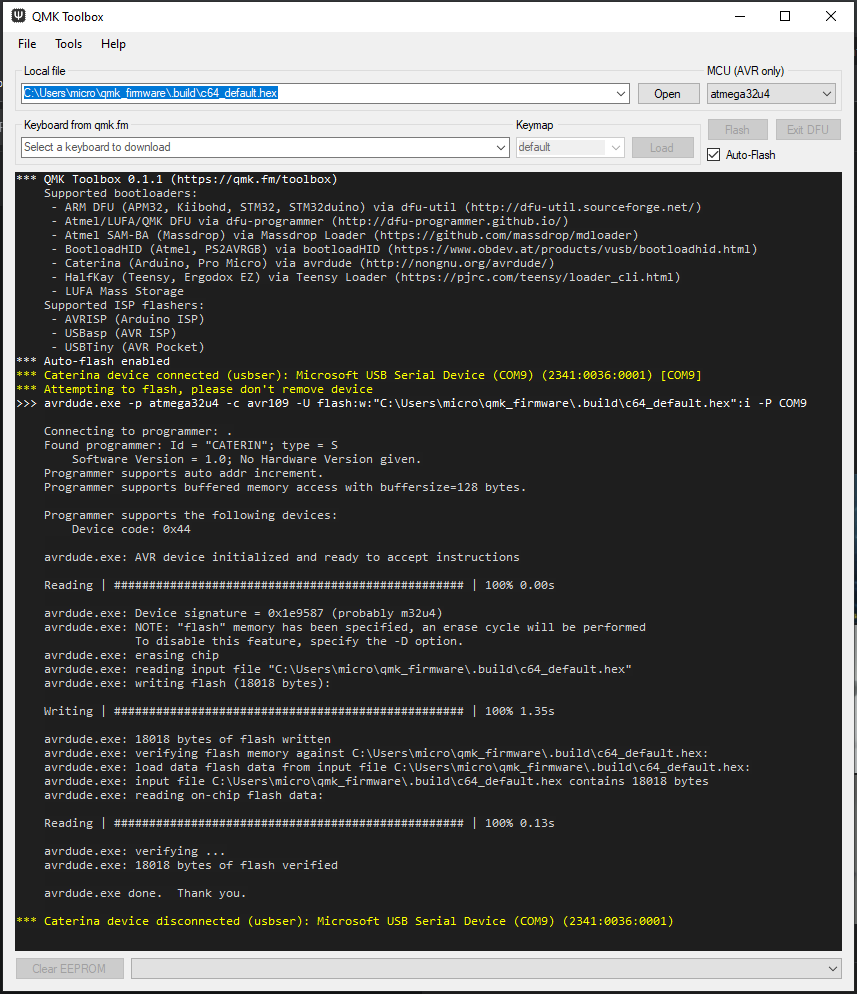

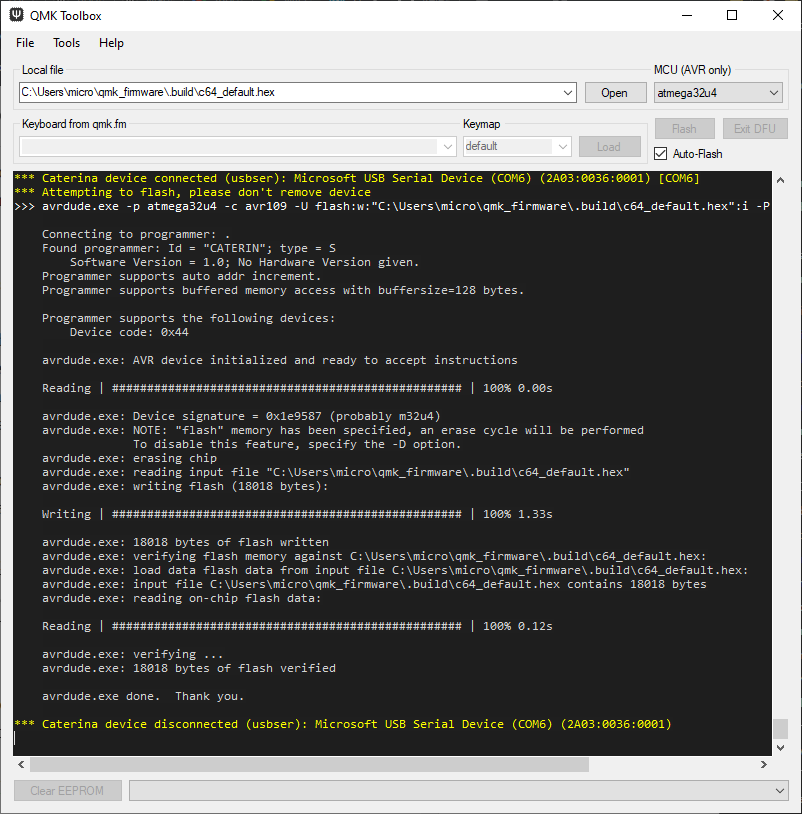

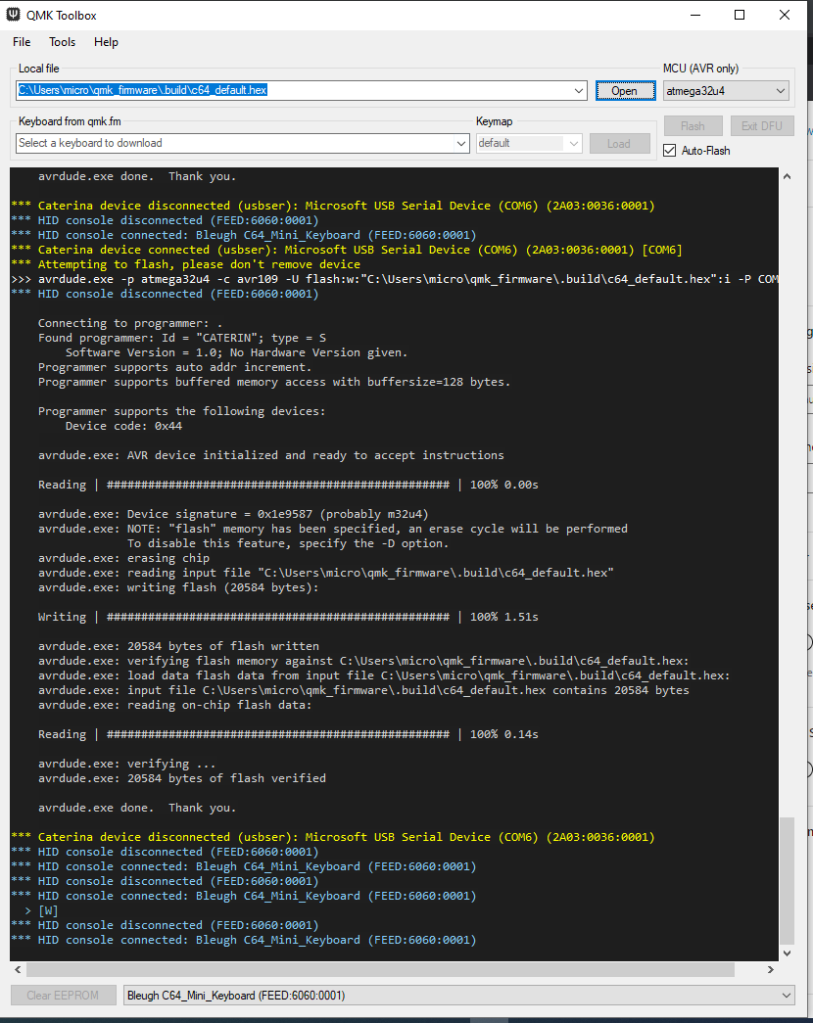

Download QMK TOOLBOX

Download the HEX FILE

Select the Downloaded HEX file from wherever you saved it

Select Auto Flash

Connect the USB arduino to your comupter

Short RST and GND on the arduino

Then, your arduino gets programmed! – Easy 🙂

Loads fixed with this – and it should hopefully be on Github soon also

The Hex File is above

There are only a couple of extremely tricky issues remaining now! they may need macros, and may not even be possible

Note with this firmware – It works perfectly with ENGLISH Language and UK Keyboard layout set in the firmware…

I hope to eventually be able to create more localised keymaps to change behaviour on boot so every language in the mini works well. IF there’s any pressing issues, please contact me, I should now be able to quickly and easily tweak a couple of keys for you.

Also, the Firmware will be part of the QMK Github soon, so you can download and tweak away yourselves!

To Upgrade your Keyboard, I’m finding QMK ToolBox to work brilliantly

Most older fimrwares out there will need to have B held down whilst shorting the reset jumper at the top of the keyboard inside , for whatever reason though t

I’ve found this a little flaky for whatever reason, sometimes mashing down every key whilst hitting reset does the trick

To make that more professional…….I now have configured the Bootmagic Lite.

To Update the firmware after this update, simply fire up QMK TOOLBOX, connect your keyboard to a Laptop. Hit ‘auto flash’, select the MCU (see picture above)…then Hold 1 and short the reset jumper inside the keyboard.

I’m still learning how configure all this, so bear with me, it’ll be slick just like those professional Mechanical Keyboards in no time*

*by ‘no tiime’ I mean potentially months and months as i’m tinkering in my limited spare time to add this extra functionality

Hi All – here goes

I’ve submitted a Pull request to the QMK Github to add the Mini !

https://github.com/qmk/qmk_firmware/pull/14159

And, here’s the firmware in a ZIP file to help

https://drive.google.com/file/d/1WVuZMWLF9_7ZtnlxLih7IebWrD0SbX_b/view?usp=sharing

That’s the QMK Code For the Arduino used inside the C64 Mini

How To Compile

Download QMK – I recommend QMK MSYS. Get it installed

There’s plenty of tutorials around

BUt, quick and easy – Unzip the above file to the KEYBOARDS folder

C:\Users\YOURCOMPUTERNAME\qmk_firmware\keyboards\

Then fire up a command prompt (Start, search, CMD, run)

and navigate to the the above folder

then run

qmk compile -kb c64 -km default

You’ll get a c64_default.hex file appear in

C:\Users\YOURCOMPUTERNAME\qmk_firmware\builds\

Now to flash –

Download QMK TOOLBOX

Arduino leonardo’s can be a little tricky to flash hex files to – be persistant – there’s two Tools that help

QMK TOOLBOX – that shows the keyboard enumerating when you plug in

Set it to ‘auto flash’ and you can try pressing / holding b and space (it’s configured as a magickey in QMK) to get the bootoader to kick in and flash the chip

If anyone knows a quicker way – shout!

And, if it helps

No PCB gerbers are public yet – play away! any suggestions, happy to look at incorporating them

I’ll follow in the future with more insight in how this lot works, and also modifications needed to get it going better… There’s a LOT to it as the Keycodes – https://sta.c64.org/cbm64pet.html

Don’t map to the HID codes used by USB…so, without some super customisation, certain combinations may never be possible

Some useful resources

https://www.c64-wiki.com/wiki/Keyboard

https://github.com/qmk/qmk_firmware

https://github.com/qmk/qmk_toolbox

https://thec64community.online/thread/688/c64-keyboard-mapping

and a few other C64 USB firmware’s i’ve found – these may have the bits needed to be able to get mine working much better – But, merging things is currently beyond my skillset – I’ll figure it out eventually

https://symlink.dk/projects/c64key/ – Has seemingly sorted out shifting, etc with custom codes. I can’t quite figure it out though

And, this awesome public project! – If you want a ready made USB interface – This looks great. Has some quite complex QMK mapping that i’ve not been able to understand – maybe it can be modded for my PCB!.

Wow, What a few weeks this has been.

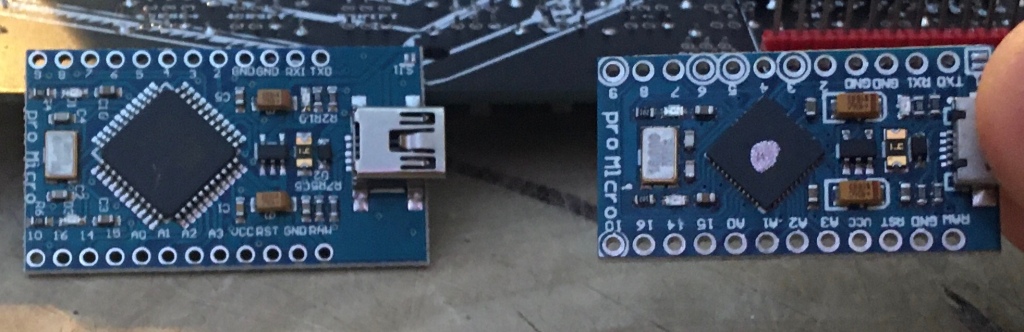

My previous QMK on my small dev laptop worked great. However, moving the directories over to my new laptop (after the kids smashed the old one) – Not working so great

I was now stuck with a handful of ‘blank’ arduinos and no way to update the firmware code, nor any easy way to flash the .hex files to them

Long story short – a friend familiar with programming Arduinos found me this

https://github.com/p1ne/arduino-leonardo-uploader

It didn’t work!….BUT playing aroudn. it at least did pickup something

So….Digging further…I found

https://github.com/p1ne/arduino-leonardo-uploader/issues/5#issuecomment-407583517

I tried the code, didn’t work

Tried again and………Woooo!

So, where i’m at now……

I can actually program up arduinos for Mini keyboard kits!

The printer actually seems to be functioning

I’m back in Business

What’s next though

Figure out QMK, I’ve found a lovely chap who’s helping out a bit to compile my keyboard into the new version of QMK being used….then I can finally start doing some development again!

and, more importantly, get this C64Mini keyboard listed in QMK for you guys to be able to easily play with the firmware….

Having some fun with the printer this past few weeks. many, many fails

Lightly used, honest

Some possible lessons learned….

1 – Don’t mix Resin brands and pigments in untested combinations

I’d ordered a bunch of ‘expired’ Elegoo translucent green resin, going ridiculously cheap, (like 1/3rd the price it should be) it prints FANTASTICALLY…BUT

….I normally use Anycubic Clear, just because it’s what i started with, and it works.

I also add various pigments from http://resin8.co.uk

Mixing in an old batch of C64 Brown with the new Elegoo didn’t really work. I had 6 failures in a row – which i’d assumed was the FEP or me doing something silly / bad levelling . The 7th failure punctured the FEP! At that point i’d realised what i’d done (mixing all the stuff together) so, ordered some new Clear resin. I got a perfect print straight away!

The thing you see above is me, changing the supports (finally) after having issues with the old base layer being too thick and seperating from the build plate. I’d gotten around this by using longer base exposures, but still, had more failures than I’d like.

Hopefully now i’ve new FEP, new resin, and spent a couple of hours doing the supports properly, I’ll get a fresh print tomorrow!

My next issue – as you can see above…QMK. I spent weeks learning how to, and setting up QMK on my old laptop, which the kids smashed.

QMK has moved on a little it seems as now there’s a dedicated QMK MSYS32 installation…BUT, it doesn’t compile my old keyboard layout. if there’s anyone good with QMK out there, give me a shout!. I’ve no doubt I can get things working again to work on the code a little, just pressed for time for the next month or two and, i’m getting the coding itch this past few days 😛

A quick pictorial ! on the process of creating keycaps.

I’ve missed out a few pictures, but this covers the basics. Using a timer, it’s around half hour all-up per keyboard. Sometimes a little more if a print fails!

Tried to make a ‘GOLD’ keyboard but need to research a little on how to keep the particles suspended. This one failed due to too much gold. It all sunk to the bottom causing layers to become underexposed and ultimately sticking to the FEP

Also tried to make a crystal clear keyboard…unfortunately I topped up the vat with a tiny bit of the gold mix from a poorly labelled bottle I use f or mixing (I didn’t write any label!) I’ll give these away with a kit to the first person that asks 🙂

Quite late into development, I’d realised that the F keys were supposed to be a different colour. So, I add two sets of F keys to kits. Some early ones went out without the extras. Happy to send some out if you shout.

Thankyou everyone for your support! Sold quite a few more kits with keycaps than expected so frantically printing away more!

If you’ve paid for a kit or just keycaps, they’re all packed and ready to go! Should take between 3 days and 3 weeks depending on where you are on the planet!

I’ll hopefully be getting more time to update on other things soon 🙂

Was just about to order another 4000 switches and take the hit…Decided to check the tracking number and FINALLY, after a month in Limbo, the switches have been released from Liege, the infamously slow sorting centre in Brussels.

SO, should be here next week and i can Finally get sending kits out!

Sorry again about the delays, I’ve now bought excessive stock so, should be able to turn around things quite quickly.

also built up a little stock of the keycaps which can be included in the kits at no additional postage cost

A quick post to show the keycaps being sent.

There’s no painting,

The letters are recessed into the keycaps and are very legible.

I’m working out postage costs as right now they’re still large letter in size here in the UK.

I probably won’t ship all of them them ‘on the supports’ as that doubles the weight

To fit them you just clip them onto your key switches

Painting. I haven’t been able to find an effective way to do that my end. A few suggestions have come in, maybe White clay would work well finished with laquer.

CAD is final now! The keycaps fit perfectly . They latch on with a push and can be removed!

Continue reading “Nailed it! Commodore 64 mini keycaps.”

Happy chappy this morning. They finished printing last night, my draining widget worked a treat – I’ll put a quick GIF up soon.

But, forgot about them until a mad panic at close to 1AM remembering I’d left them on the printer. With these, you can’t as the resin in the concave surfaces will part set in the morning and cause an uneven surface.

So, quickly washed them in IPA, regretted it immediately as it was dirty. Did another wash in IPA to clean the resin and straight to the hot water tap and larger bowl with a brush to clean off the bits. I’ll strain out the bowl later.

Final tweak needed now is the amount of grip to the switches themselves, shrinkage is variable at the moment, can’t go too small or keycaps may break when putting on, can’t go too big or they’ll be too wobbly and fall off.

May need to go middle ground and require a tiny blob of something sticky in each keycap, I’ll know soon enough!

Has some successes with varying mixes of pigments! Wifey demanded I do a bronze one.

Fine adjustments needed only now and it’ll be a wrap.

….problem is, fine adjustments’ll probably take another 80% of the total :-p

Now, gotta figure out how to get Arduinos quickly as 50 wrong ones just turned up and due to Chinese New Year my expedited (expensive) DHL delivery won’t leave for a couple of weeks, D’oh! Best laid plans….

Well, final furlong for the 3D printing part anyway! Next step, investigating colouring in

Couple of successful prints! Rev 6 – just binging in stuff and hoping it works.

Rev 7 – more scientific and better CAD – all letters are now 0.2mm wider and deeper. This tiny tweak shows spectacularly well just how big a difference small changes can make.

Still some more CAD to do but soo close to final now!

And, finally, the print itself. I’ve learned that supports are critical here. Lots of them!

There’s actually as much material here in the supports as there is in the keycaps, but if you scrimp a little and try to reduce the amount, check out the top left of the picture below. I lost the return key and a few smaller keys were taken with it.

This was a calculated ‘risk’ by leaving this section to just have the standard auto generated supports, every other area had super dense supports.

There will be a middle ground, which I’m working on as I’d like to offer these cheaply…less resin used = cheaper to make!

Also, note the rest of the supports. THey are SO EASY to remove. When I offer these keycaps for sale, again to reduce cost, I’ll probably leave them as you see here. Makes for more robust packing and if you decide to paint them, you already have them held down on a convenient stand!

Well, experiment 1 worked a treat!

I purchased this pigment from Resin8

https://www.resin8.co.uk/opaque-resin-pigment—rich-brown-9247-p.asp

Added a blob – maybe 1-2ml worth off the end of a lollipop stick

Stirred that in with 150ml (well, about 150g by weight as that’s far easier, and it’s close enough) of Anycubic grey resin

And….

Very happy! Considering this is literally bunging stuff in and seeing what happened.

Still some way to go now to try the other clear resin and white resins, also tweaking the colours

Also have I some distortion issues on these keys but those are under control as there’s a very clear relationship between support structures and distortion/warping and underside finish!

I think I’m on track for a March launch!

Started a print tonight! Version 6 🙂

That colour may not look correct but it’s not intended to be perfect,

I need to iterate this process slowly and scientifically so I can recreate the colour at any time.

Best place to start is from a known working point and changing a single variable at a time to get to where you want to be

Here, I’m starting with the resin I know works – drab grey.

I’m adding an unknown if it works brown pigment just to see what happens!

If that prints, I can try adding black pigment to make it darker brown.

If it doesn’t, I can try using a CMYK mix of colours to make the correct Brown

Once I get that shade, I can try different resin bases to see what gives the best finish! Maybe clear + brown or white +CMYK will do the job!

I’ll be iterating the CAD model and the colouring at the same time!

Hopefully this new CAD model will fix the minor offset issues with the keyboard, shifting all the keys slightly to the right also allowing me to finally reveal a working test fit!

One small thing I picked up when test fitting my first attempt, I’d not perfectly centred the left shift key button and Return buttons on the PCB. It doesn’t matter in the grand scheme of things as hacking your own keycaps doesn’t need perfect alignment on the wider keys, only the 1 wide keys

Where it is annoying though is I can’t correct this error or any keycaps I make now won’t perfectly align on old keyboards! Heh, what’s 1/2mm between friends eh!

If you’ve purchased a kit this past couple of weeks, it’s now been posted.

I’ve only 1 remaining kit to post, but first I have to solder it (Mr L D from Italy, I’ll start it this weekend)

I’m doubling down on keycap development now, hoping to have those ready in time for new stock

Let’s say March 1st to be safe, hopefully a little sooner if parts arrive quicker 🙂

This one went well 🙂

Note, the intentional ‘stone effect’ finish 😉

Most people would say this was caused by an over excited person, whom, upon waking early and discovering the complete print decided to not follow the correct drying / washing procedures in order to get it finished quickly!

I, err, disagree…

Either way, I now have a firm grasp of changes needed to the CAD model and also the supports needed in the slicer.

Those changes are fairly substantial, so I expect it’ll be a little while for my next update, happy to document them also if anyone’s interested.

Wow! An exciting day today.

After quite some nervous trepidation, I finally shoved some resin into the printer and achieved my first ever resin print.

And, amazingly, some stuff worked! Significantly more than I’d expected to work actually.

I’ve been quite ‘scared’ of actually starting a print, I‘ve read too much about toxicity and fumes, which aren’t things you want with two young kids.

Well, I spent a couple of hours doing some final reading, and setting up on the dining room table. Levelled the bed, levelled it again. Shoved in the resin and…a Spectacular success for me!

I know the print failed mainly due to poor supports, some text is also too fine. Both were concerns with the cad and the slicer and easily fixed 🙂 there’s probably a dozen other issues I’ve not found yet also (it’s been 30 minutes since I wash and cured them fresh off the printer)

Next step, iterating, optimising . It could be done in a few weeks at print 3, it could be print 10 and take a few months , but now I’m over the first hurdle, onwards and upwards!!

Only a heads up that if you’ve ordered a kit between Xmas day and today, it’s just been posted 🙂 .

Had hoped to get them out Monday/Tuesday but the government lockdown okey-cokey and homeschooling prevented that.

At least it’s earlier than Saturday :-p

It’s going to be a while yet, but I’ve finally fixed some long standing issues with the keyboard model i’ve been building in Fusion360

The main issue was a badly created model!. I’ve junked quite a lot and started back prior to when some odd dependencies crept in and really put some roadblocks on scaling things correctly and adding finishing touches.

But, it’s been worth it

That previous picture is the underside of the Keyboard – Those holes in the keys are 2.2 x 2.8 holes. it’s a first run at fitting the key switches into the keycaps. a lot more iteration needed to hollow it out a little and create some form of inbuilt snap-fit with stress relief, but…it’s a start!

The silver / grey keys over on the left are the ‘parent’ keys

If I make an update to the curves or size of a parent key – it rolls out to all the same sized keys in its row

if I need to iterate the hole size for the key switches, I simply change a few parameters for the hole size and it rolls out to all the keys in one go.

I’ve taken so long to develop it parametrically as it’ll now be so much quicker to iterate

and, here’s a new render!……..going to spend the next few weeks iterating, and hopefully over Christmas , fire up the resin 3D printer for the first time!

Just realised that it’s not easy to find an image to show what’s in a kit.

Here goes

what you need to add;

What’s In the Kit

C64 Mini not included, but this is what yours will look like once you’ve assembled the kit

Coming at some point in the future (late 2021 at this rate) – 3D, resin printed Keycaps!

A very talented Hans Liss from the Facebook group – TheC64 Mini has make a perfect assembled kit.

Drool over the photos below

Note the extras like the hacked up USB hub to make it slimline

The Extra UART connector that he’s added, and the nigh on perfect Keybaord keycap butchery!

Hans also helped by pointing out a few errors i’ve made with the original firmware sent out with the kits. I spent a couple of weeks figuring out how to fix it and have a new HEX file for those that want it.

There’s still some ‘not quite exactly commodore’ quirkery happening – which i’m working on, but i’ll bet that 99% of you won’t be able to figure it out. I’ve only found out due to Hans’s extensive knowledge of the C64 inner workings and also me, downloading the original user manual for the Commodore 64.

New Firmware upgrade available

It’s been an intense and frustrating few months trying to figure out QMK in spare time here and there – today, something ‘clicked’ and…..I’ve made a new keymap.

Please email me – KEYBOARD AT BLEUGH DOT BIZ for a new HEX file. also happy to help you flashing the thing with the Arduino IDE (it’s quite easy!)

Why I developed a new keymap

A couple of users have reported that the key mapping is a little wrong when plugged into the mini.

By ‘key mapping’ it means, when you press a key, or combination of keys, you don’t get the character that’s shown on the keycap.

Most people will know this if they’ve ever used a US keyboard on a UK computer or vice versa, that Shift and 2 gets annoying after a while when you’re trying for the @ sign!

So, I’ve dun fixed those minor niggles that people observed….AND, i’ve gone and added quite a bit more!

Continue reading “C64 Mini Keyboard Kit – New Firmware available”Batches 4 and 5 have started arriving! Here’s some pictures from a happy user who only received it a couple of days ago 🙂

Great soldering job 🙂

A quick post to point you to a YouTube link

The user’s gone into some detail about potential gotchas when doing the build

Thankyou for posting such an informative video and can’t wait to see it running in the mini 🙂

Have been promising a long time to do this, so finally took a few hours to butcher another mini!

As you can see, for the most part, it’s pretty good, but NOT perfect

what I’ve discovered…..

2 part epoxy works best

Each keycap row is a different depth – the top one needs the least glue, row 3 the most

My errors here. I used a hard plastic glue from Bostick. it doesn’t grip well enough on the top of the keyswitches. I glued everything, waited a few hours, half the keycaps didn’t stick

glued the rest, waited, half again didnt’ stick…rinse and repeat about 6 times, adding more glue till finally they all stuck.

The 2 part epoxy stuck fast and hard! – but I used too much.

The repeated adding of more glue caused the multiple key levels you can see in the picture

I’ll try one more time I think!