Just over a year ago I purchased my Creality Ender 3 Pro…an absoloute steal at about £140 after discounts and Topcashback special offer at the time.

I was having so much ‘fun’ with my Wanhao Duplicator 9 that I didn’t open the box for nearly 1/2 a year. and I only fired the thing up a few months ago!

I have to say, I’m impressed. The printer deserves its rabid fanbase following. It printed flawlessly out of the box without any setting up.

It’s surprising the difference having a reliable ‘work horse’ printer makes to the hobby. I need a bit – I just go print it. no faffing about with levelling and bed adhesion.

Till it doesn’t…….

Note, if your previously reliable printer seems to under-extrude, even on known great filament – try the extruder arm.

Something seemed ‘off’ when printing standard stuff – almost overnight the printer just seemed to under-extrude, not be reliable and, well, become more like my Wanhao D9 (a bit crap)

Even bizzarely, the printer would print OK over to the left, but under-extrude to the right. Took an hour to diagnose this! When the head was over to the right – it would pull the mechanism slightly which dislodged the arm enough to slip the filament.

Luckily, This extruder tech hasn’t moved in years…….An unassembled, missing parts kit I picked up off facebook a couple of years ago (syntek, sintek or something similar) which itself was a few years old had just the part..(which complete, looks identical to this Aliexpress one …..

Works a treat….

Except….There’s those new fangled ‘dual gear’ type extruders they’re on about….

and….well, I have a LOT more spares upstairs that i’ve gathered!

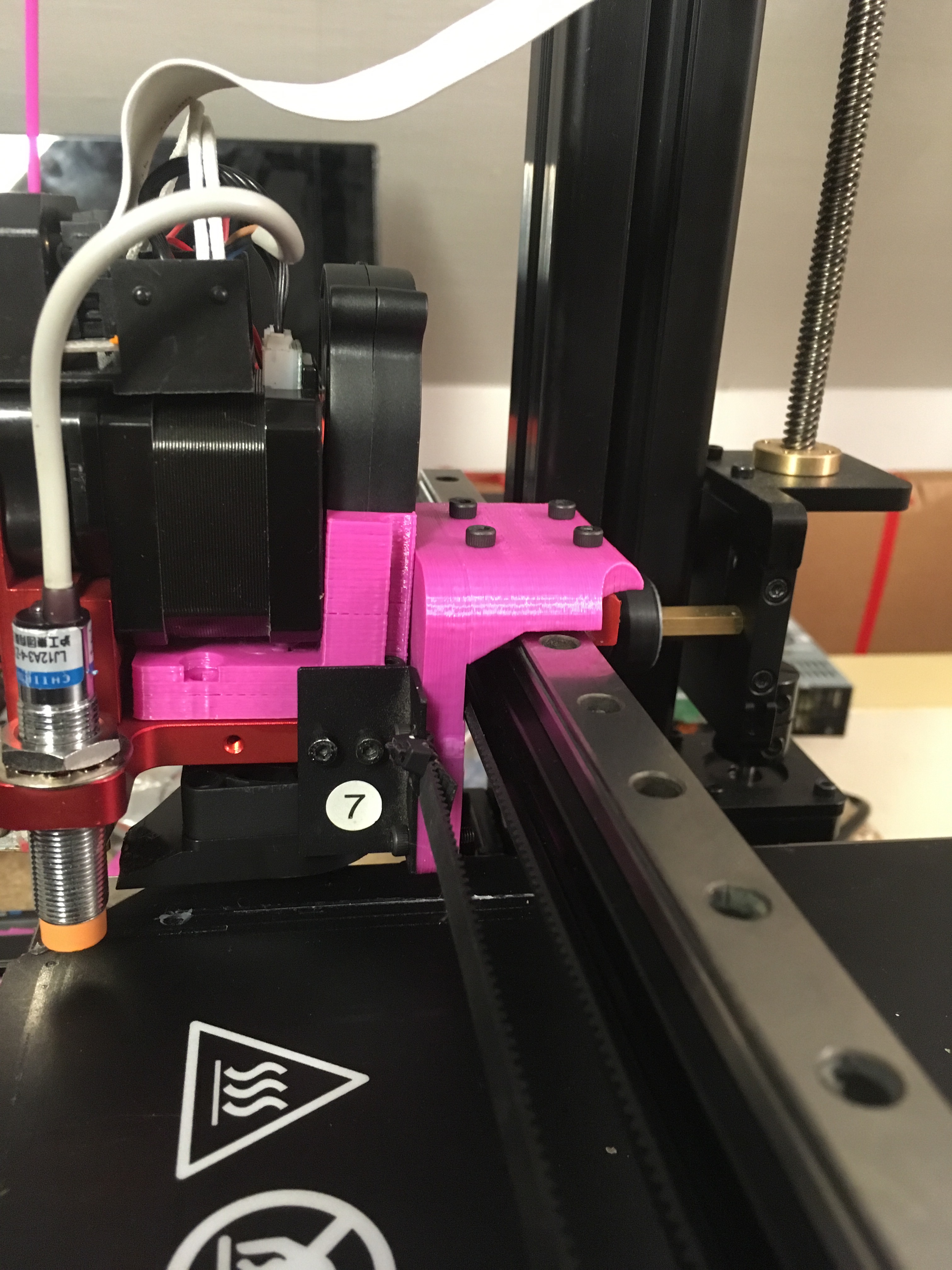

And, well, if i’m upgrading one extruder drive mechanism, it’s shockingly easy to add a second….

and…

Fortunately (for the Ender 3) , My Wanhao Duplicator 9 decided to ‘blow up’ a bit *Probably assisted by my dual 5015 blower fan mods

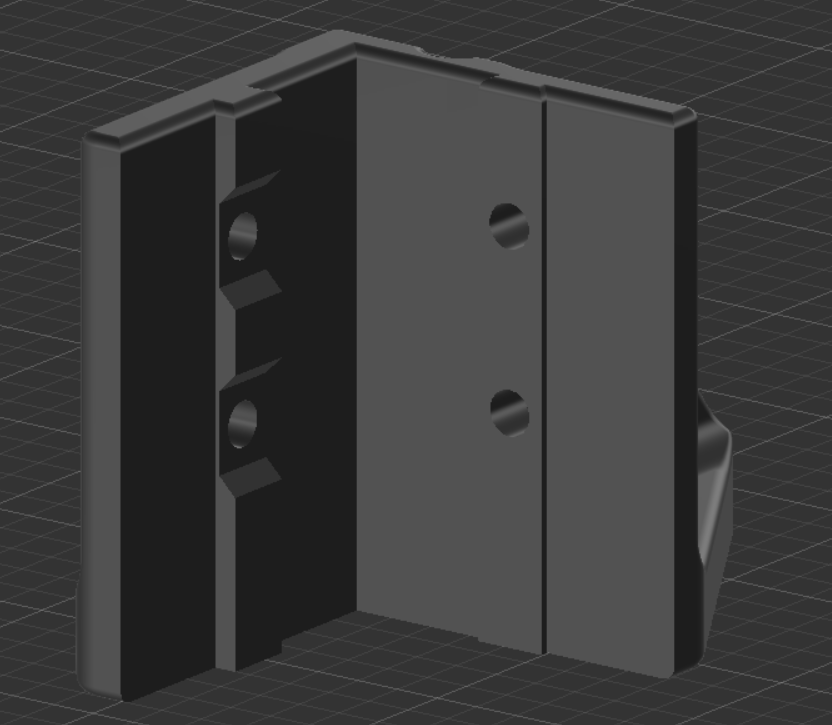

So, now, my D’s guts, kinda look like this……..

What’s best! – I now have a working 3D printer that I can use to print parts for my broken 3D printer!

Wooo

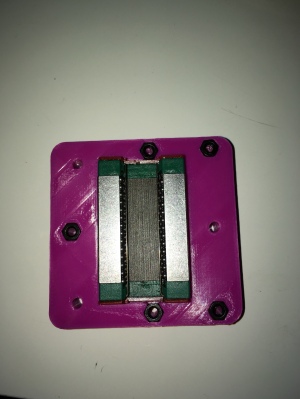

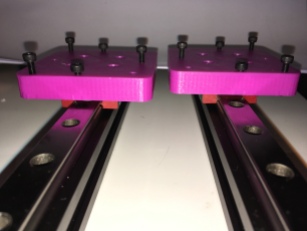

Now, looking at dual extruder mods……… – https://www.thingiverse.com/bleugh/collections/3d-printer-carriage

looks like my tinkering time’s filled up again. gotta get designing a ‘fix’ for the D9…and a dual extruder / colour setup……

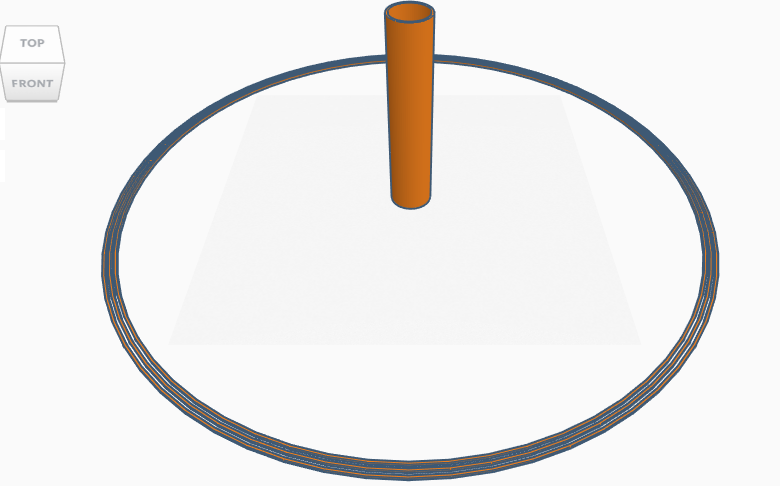

Just running through a few ideas in

Just running through a few ideas in

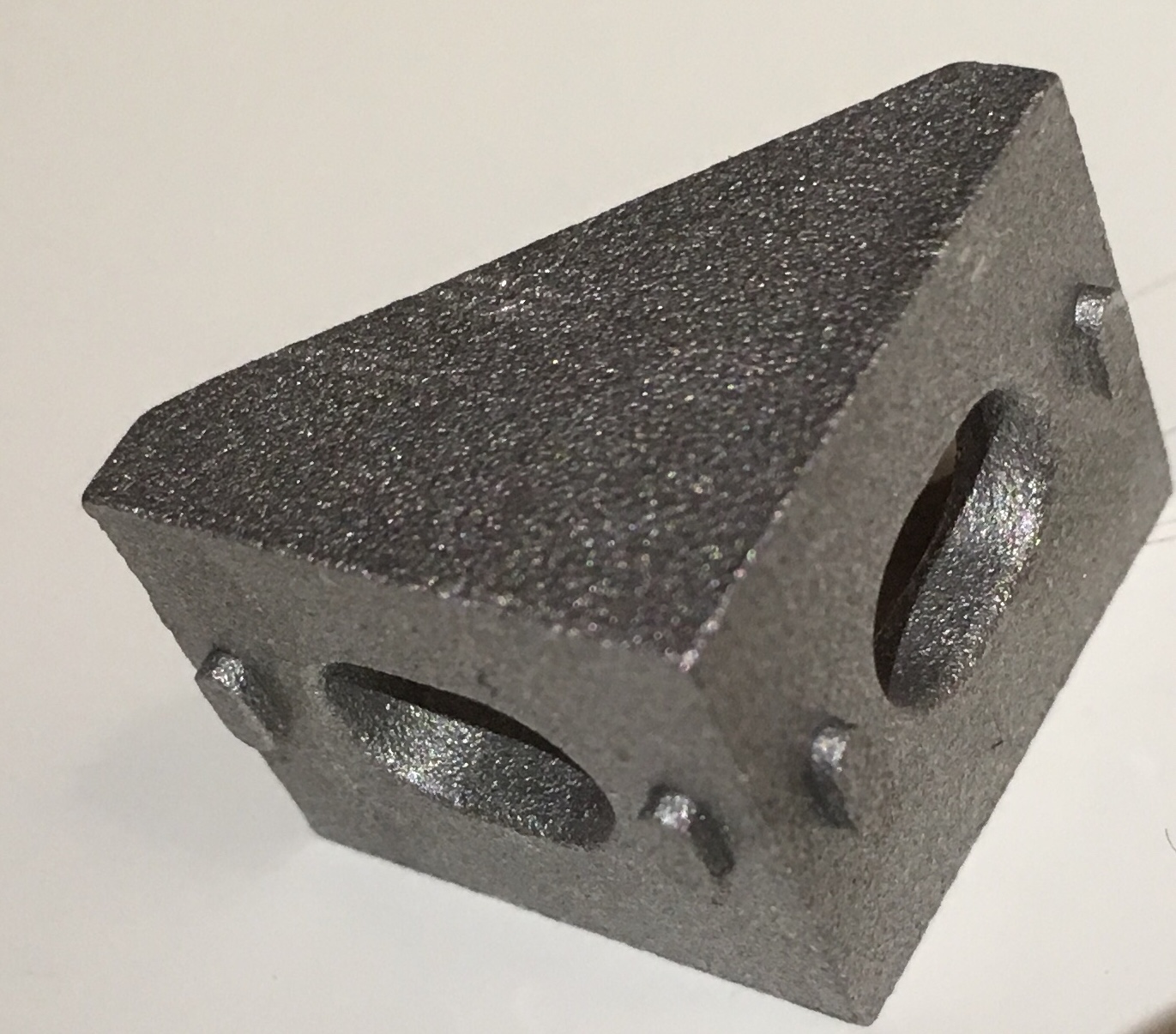

Finally –

Finally –