Find it at the link below.

https://www.thingiverse.com/thing:3350971/

This reduces the ‘inset’ part’s height so that it doesn’t sit so far into the top of the 40×40 extrusion and also adds two notches (at 45 degrees so should still print just fine without supports)

These notches should allow easier location and locking in of T-Nuts

May get off my backside and polish off a few more ideas for upgrades in the near future!

Hi, I just wanted to stop by and thank you for the Wanhao D9 blog entries and your ‘fixes’ on Thingiverse. I purchased my Mk1 D9 18 months ago. I had terrible print quality problems when I first got it, then a blown splitter board, then a malfunction of the mainboard (both replaced by Wanhao, eventually). I had pretty much given up on the printer and was about to dismantle it for parts when I came across your blog. To cut a long story short, I have added linear rails to all 3 axes and added your X axis fixes, Y axis tensioner and motor mount and a few other bits and pieces and now the D9 is actually working well.

Cheers

Pete

LikeLike

Thanks for the comments Pete :-)the D9 is a ‘painful’ printer for sure, BUT, it’s taught me a lot about 3D printers 🙂 Good luck

LikeLike

Hi again,

Have you considered upgrading to a newer controller? I am looking into the possibility but the options are a little overwhelming. Would appreciate any pointers you can give.

LikeLike

Hi.

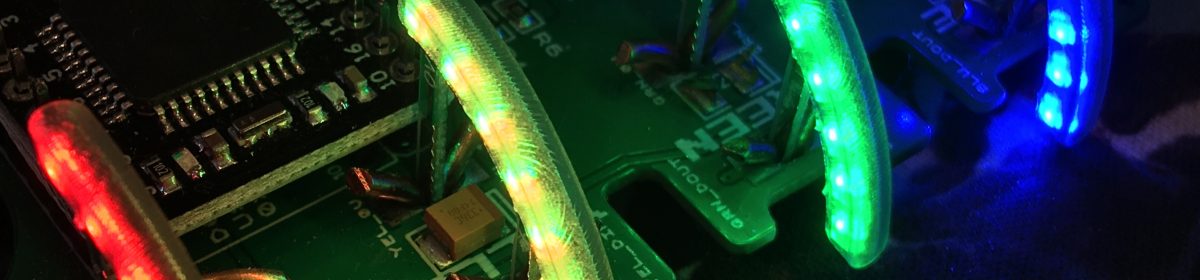

I have purchased the SKR1.1 and then a 1.3 with TMC2008’s

Also got a TFT35 and 2.4!!

I haven’t gotten around to fitting them yet (too many side projects, too little time) but some people have! Check the Biqu SKR users group on Facebook!

Also you may want to look at the new waggster firmware (pretendprusa website) as tats now working a treat with the stock board and LCD

LikeLike

D9 Y axis Bracket is fantastic the printing qualyty change a lot, but somebody is thinging how to cool the Y motor?

LikeLike

Best thing to do is to install a larger motor on, Or cheaper – put a significantly lighter bed on. instead of pressed steel, junk that and mount an aluminium plate. put a new heater on whilst you’re there, and then a glass bed. The stock bed is ridiculously heavy. that’s why the stepper motor heats up too much.

LikeLike