I’ve now printed a good handful of test keyboards, got them pretty dialled in with the old Standard resin.

I’m now switching to a more robust ABS like resin, and, have discovered some interesting quirks

Who’d have thought that being ‘too airtight’and having too good / close tolerances would have been a problem!

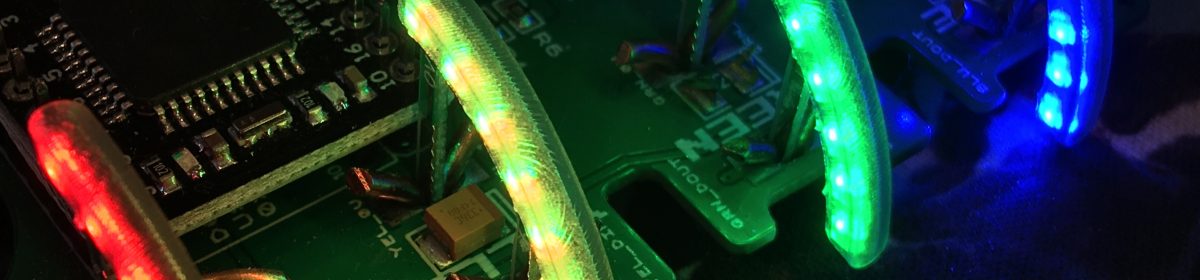

Firstly, here’s a super close-up showing the now *perfect* letter formation with the new resin , I have the exposure almost perfectly dialled in

BUT, there’s a small issue. When fitted to the keyboard, The Keycaps all sit at differing heights.

I did some experimentation and discovered that the new resin and exposure settings are so precise that air and liquid from poor drying are being trapped when pushing the keycap onto the stem of the switch!…

Yep, It’s AIRTIGHT.

When there’s a little more tightness for the stem jamming in the hole, the cavity above the switch stem holds more air / whatever, so it becomes larger, and the keycap sits higher as it can’t be pushed down onto the stem.

I’ve possibly inadvertently created the world’s first air-damped/suspended keycap mechanism?

Who’d have thought it.

The solution of course is to prevent these pockets of air being captured in the first place…….

So, TWO HOURS and 96 manual sketch creations (and a post on Fusion forums to request a feature add to save about 600 mouse movements and clicks in future) I’ve added a small channel next to each keystem hole to ‘let the air out’ whilst i gently mash down the keycaps……

Of course, now this process is all fine tuned, a manufacturer would go and release, what seems on paper to be the PERFECT miniature keyboard keyswitch.

and, another manufacturer releases one that’s better, but not perfect.

So, More keyswitch samples on order, I may eventually have to re-do the whole switch assembly in the future IF these switches are as good as i hope!

(and i’ll re-purpose the 6000 purchased for my Spectrum Next mini project which doesn’t need the new ‘perfect’switch features)